Smart Factory positioning management system is based on UWB positioning technology as the underlying data sensing, the label in the device and the base station communicate through UWB pulse signal, the base station will collect the label information data and forward to the positioning server, the data is processed by the positioning engine algorithm, and the accurate location information is transmitted to the upper layer application through the open AP1 interface.

By setting up a limited number of positioning base stations in the factory, the location labels of employees and assets can be accurately located in real time, and the location information of people and objects can be displayed in the factory control center without delay, so as to carry out security area control, personnel on duty monitoring and real-time track monitoring of materials. Precision reaches 10cm level, precise control to lean production, reasonable scheduling and arrangement, improve the management level of smart factory.

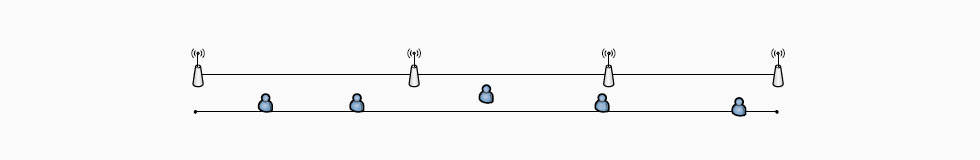

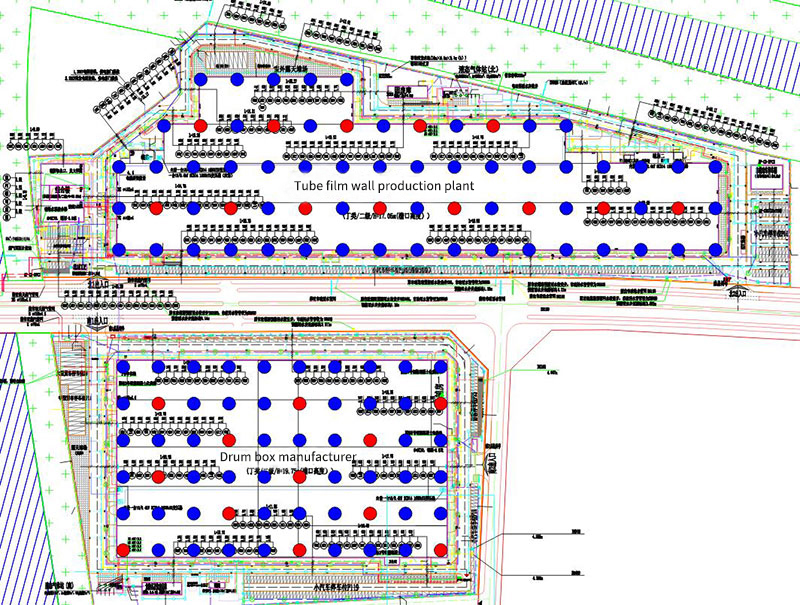

For the narrow and long positioning area, our company adopts one-dimensional positioning scheme and deploys multiple UWB base stations according to the aisle direction. It is only necessary to locate the real-time relative position of the target in this roadway, as shown in the figure below. Due to the small width, the width of roadway is generally ignored when doing indoor positioning.

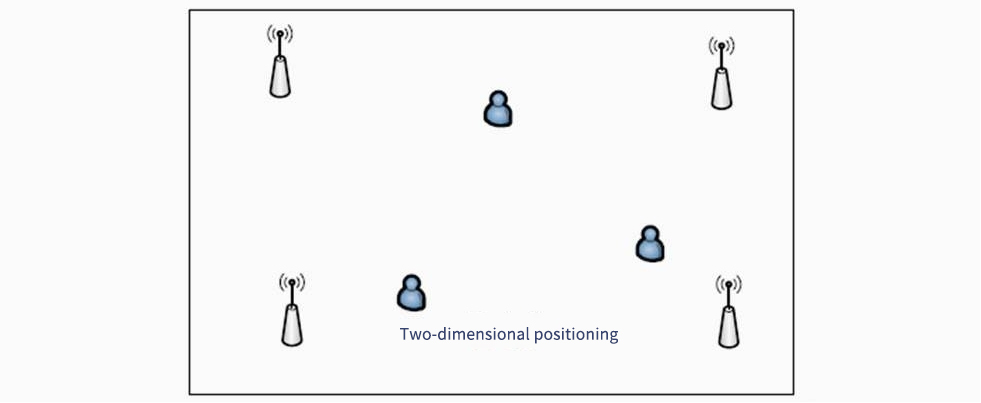

For large-area positioning area, the solution we adopt is two-dimensional positioning. By deploying more than 3 UWB base stations, we can determine the real-time location of UWB labels in a standard two-dimensional plane. The real-time two-dimensional coordinates of UWB tags can be measured.

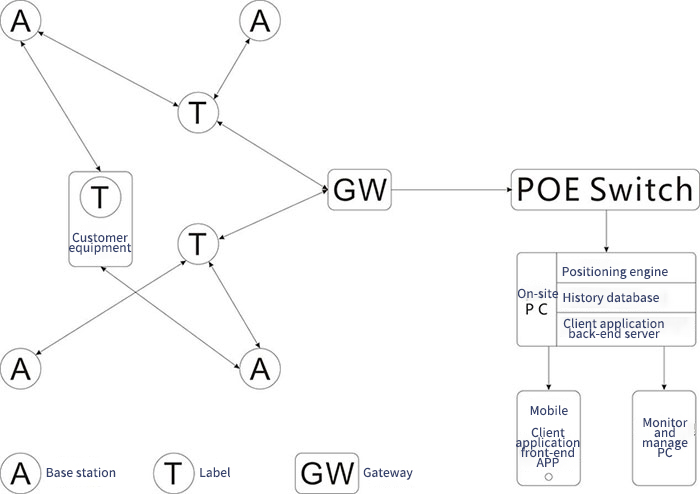

Scheme topology

UWB positioning system architecture includes UWB base station, UWB label, UWB gateway, UWB positioning engine algorithm, UWB positioning software, etc.

The location gateway collects location data of all labels within the signal range and pushes the data out over Ethernet. At the same time, the UWB positioning engine software middleware is connected with the gateway, and then the middleware uses the standard MQTT protocol to transmit the positioning data.

Overall design

In this scheme, a UWB base station is deployed every 30 meters in the pipe film wall production plant area for two-dimensional positioning, and the location information of positioning labels on employees and assets can be accurately obtained in real time. For corridor and other narrow areas, a UWB base station is deployed every 30 meters for one-dimensional positioning of UWB.

One gateway is deployed every 60 to 90 meters to cover as many locations as possible. Generally deployed on the top of a building, such as the roof, to radiate down the signal.

Technological advantage

High precision positioning:

Indoor and outdoor precise positioning adopts UwB technology and supports ToF positioning method, which can meet the requirements of indoor and outdoor products respectively. The positioning accuracy varies according to different scenes, and the maximum positioning accuracy can reach 1 m ~10 cm.

High speed data transmission:

The gateway transmits data back through Ethernet to ensure high-speed data transmission.

Local label coordinate calculation function:

Can not need remote server, remote server computing power requirements are low.

Seamless system access:

The positioning engine uses MQTT protocol to minimize the company's R&D investment and cost input, and users can quickly access their own system.

Convenient for construction:

Optional card installation, column installation, magnetic installation and a variety of installation methods.

Achieve effect

Real-time positioning:

Personnel, vehicles, materials, carrying instruments and other elements of real-time accurate location.

Track tracking:

Review historical activity track, identify invalid activity, optimize the work flow.

Intelligent scheduling:

Real-time monitoring of personnel material location information, intelligent scheduling.

Intelligent alarm:

Personnel trespass warning area alarm, one key call alarm.

System composition

WAT1001 Locating the base station

Power supply voltage: external DC power supply, 7 ~ 30V

Positioning accuracy: 10cm

Location protocol: IEEE 802.15.4-2011

Foot inch: Diameter 68mm*52mm (height)

Wireless transmission mode: UWB

Coverage range: 80m diameter range

Operating temperature: -30℃ ~ 70℃

Data interface: UWB wireless pulse transmission

UWB-1000E Locates the gateway

Power supply: POE power supply is supported

Positioning accuracy: 10cm

Foot: 165mm in diameter *31mm in height

Wireless transmission mode: UWB

Coverage range: 80m diameter range

Operating temperature: -30℃ ~ 70℃

Data interface: Ethernet, UWB wireless pulse transmission

UWB-20T locator card

Power supply: Rechargeable lithium battery

Positioning accuracy: 10cm

Size: 110mm*60mm*9.8mm

Wireless transmission mode: UWB

Operating temperature: -30℃ ~ 70℃

Data interface: UWB wireless pulse transmission

|

Last:UWB tunnel corridor positioning

NextIntelligent factory personnel location solution |

Return |