Scheme background

The raw material cost accounts for more than 60% of the total product cost of glass deep processing enterprises, so it is of great significance to do a good job in the control of raw material inventory. Medium and large glass enterprises have a wide range of product specifications and models, especially the glass factory manufacturers have a large number of products every day. With the application of new technology and the development of new products, the types of glass are still increasing, and the amount of information collected is also expanding. Using the warehouse management system based on UWB, the operator can be very convenient in the management platform to complete the glass warehousing, warehousing, inventory and other work.

Existing problems:

1) The management of glass warehouse is chaotic, and the implementation of existing system is not in place

The current reality is that the management of the glass warehouse is chaotic and the accounts are not consistent. The direct result of this is the uncertainty of the company's assets and the inaccuracy of cost accounting, resulting in the inaccuracy of the company's profits.

2) The storage classification of glass materials is not clear, the storage is not reasonable, and it cannot achieve first-in, first-out

Due to the large number of glass materials in the warehouse, they are not well classified according to the storage batch. For each batch of goods in storage, the storage time is not clear, so it is impossible to do first-in first-out. As a result, some glass purchased in advance is overstocked in the warehouse. Take up space.

3) There are too many glass materials stored, and it is impossible to grasp the storage situation of glass materials in the warehouse in real time

Inventory control is one of the core of enterprise material management. At present, there is such a phenomenon in the inventory control of the company. Because of the large storage of glass in the warehouse, coupled with the chaos of warehouse management, it can not accurately grasp the inventory situation.

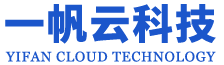

UWb Material locating solution

The material positioning scheme of glass factory adopts the wireless pulse technology of Yifan Cloud Technology. By placing a reasonable number of positioning base stations on the top of the workshop, continuously collecting the spatio-temporal coordinate data of various elements returned by UWB labels on the glass shelf, and locating the materials in the warehouse and production workshop with high precision, the spatial location and order information of all materials and products are obtained.

It can make the coordination and cooperation between various departments smoother, advance warning of material shortage and material shortage, arrange the production sequence reasonably according to the production situation of the production line, order emergency degree and material overall planning, provide the production efficiency of the factory, and greatly reduce the occurrence of production accidents caused by material shortage and production scheduling conflict.

Site installation effect picture

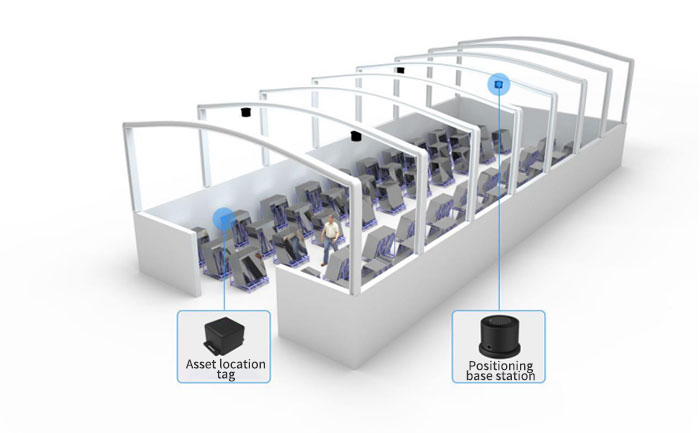

Base station gateway plan

A UWB positioning base station and a UWB positioning gateway are deployed every 25 meters and every 40 meters in the energy-saving glass workshop.

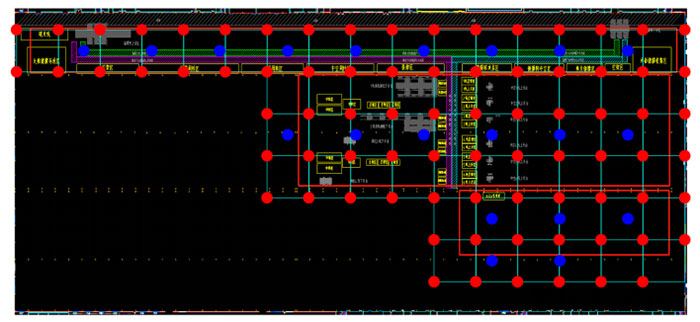

Solution architecture

The whole high precision positioning system consists of positioning tag, positioning base station, positioning engine and application platform. The location tag and the location base station communicate through UWB signals. The location base station transmits the location tag data received to the UWB location gateway through UWB signals. The location gateway sends data to the location engine through Ethernet for data analysis and processing, and transmits the processed precise location to the upper-layer application through an open API interface.

System composition

WAT1001 Locating the base station

Power supply voltage: external DC power supply, 7 ~ 30V

Positioning accuracy: 10cm

Location protocol: IEEE 802.15.4-2011

Foot inch: Diameter 68mm*52mm (height)

Wireless transmission mode: UWB

Coverage range: 60m diameter range

Operating temperature: -30℃ ~ 70℃

WGT1001 UWB Locate the gateway

Foot inch: Diameter 80mm*54mm (height)

Power supply: POE power supply is supported

Wireless transmission mode: UWB

Positioning accuracy: 10cm

Coverage range: 80m diameter range

Operating temperature: -30℃~+70℃

Asset location tag

Acceleration triaxial sensor, UWB pulse communication technology

Location algorithm: TOF

Location mode: UWB

Power supply: Rechargeable lithium battery

Battery life: 7X24 hours (using onboard motion sensor,

And activate the tag only when needed to extend battery life even longer.)

Wireless transmission mode: UWB

Operating temperature: -30~70℃

Positioning accuracy: 10cm

System function

Location mapping service; Map can be zoomed, dragged, multi-map switch; Click any label to view the glass name, glass number batch and other information; Common maps such as png.jpg are supported

Real-time track display

Real-time tracking mode such as arbitrary labels; Label power monitoring, low power warning

Electronic fencing and alarm management

In/out of fence area alarm mode, after the electronic fence is opened, the system will monitor the positioning label in the fence, if the shelf is unauthorized to enter and leave the shelf, it will alarm.

|

Last:UWB tunnel corridor positioning

NextIntelligent factory personnel location solution |

Return |